Home LED Light Products Ce Certificate Warehouse Storage Radio Shuttle Rack/Warehouse Storage Rack/Shuttle Rack

Ce Certificate Warehouse Storage Radio Shuttle Rack/Warehouse Storage Rack/Shuttle Rack

| Price: | US $ 20000/Piece |

|---|---|

| Min Order: | 1/Piece |

| Pay Type: | L/C,T/T,D/P,Western Union |

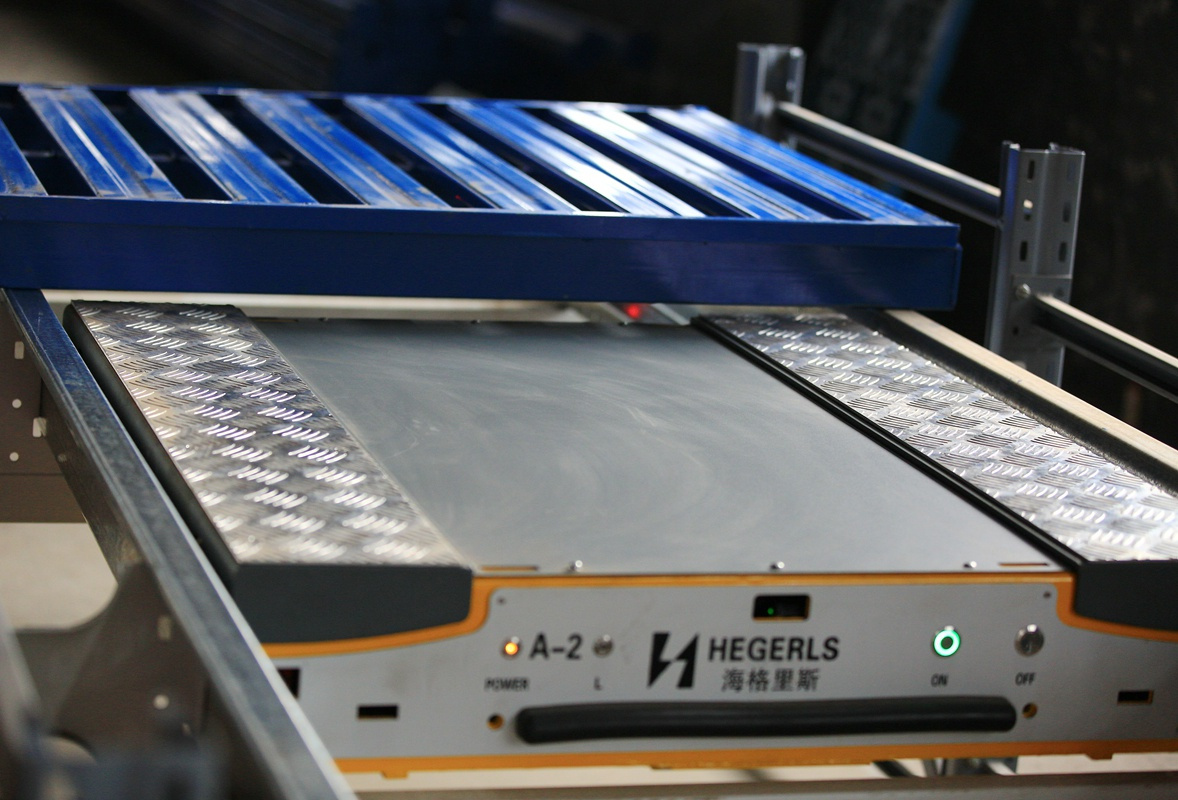

| Prod Model: | HGLS-RDST058 |

|---|---|

| Loading: | 1.5tons |

| Temperature: | Minus 25 Degree |

| Unloading Speed: | 1.2m/S |

| Loading Speed: | 0.8m/S |

| Lift Time: | 0.8s |

| Material: | Steel |

| Mobility: | Adjustable |

| Height: | 5-15m |

| Closed: | Open |

| Development: | New Type |

| Serviceability: | for Special Purpose |

| Structure: | Automatic |

| Type: | Automatic |

| Weight: | 1000-1500kgs |

Product Description

CE certificate warehouse storage radio shuttle rack/Warehouse storage rack/Shuttle rack| Radio Shuttle / Radio Guide Vechile | Model | ||||||||

| Item | parameter | RGV-500 | RGV-1000 | RGV-1500 | |||||

| 1 | Suitable Pallets : | ||||||||

| 1.1 | Standard Pallet: L x W mm | W1200 X D1000mm | |||||||

| 1.2 | Size Range Available :L x W mm | W1100 ~1250, D800 ~1100mm | |||||||

| 1.3 | Styles of Pallet Bottom | "" or"" | |||||||

| 1.4 | Material of Pallet | Wood,Plastics,Steel | |||||||

| 1.5 | Deflection of Pallet | Max 20mm | |||||||

| 2 | Total Weight of Loading | Max 500Kg | Max 1000Kg | Max 1500Kg | |||||

| 3 | Model of Running | In the rails | |||||||

| 4 | Data of Running: | ||||||||

| 4.1 | no load Running | 1.1m/s | |||||||

| 4.2 | full load Running | 0.9 m/s | 0.7 m/s | 0.5 m/s | |||||

| 5 | lift parameter | ||||||||

| 5.1 | Time of Single Lift | 2s | 2.3s | 2.5s | |||||

| 5.2 | height of Lift | 40mm | |||||||

| 5.3 | space between pallet and rail | 13mm | |||||||

| 6 | specification of RSC: | ||||||||

| 6.1 | Outside Dimensions L x W x Hmm | L1100xW977x 198mm | |||||||

| 6.2 | Weight of RSC | 242Kg | 268Kg | 300Kg | |||||

| 6.3 | Plate Size of Equipment | L1030xW185xT3.5mm,2Pcs | |||||||

| 6.4 | Inner Width of Fork | 230mm | |||||||

| 6.5 | Width of Single Fork | 236mm | |||||||

| 7 | Driver Motor for movement | Lenze 24V 370W | |||||||

| 8 | Wheels of Running | φ120mm Vulkollan | |||||||

| 9 | Driver Motor for Lifting | Lenze 24V 370W | |||||||

| 10 | Battery Capacity | 24V 60AH | |||||||

| 11 | Weight of Battery | 20Kg | |||||||

| 12 | Charge times | 900 | |||||||

| 13 | Duration of Charging | About 5 hours | |||||||

| 14 | Method of Remote Control | Radio Frequency 433MHz,3.7V 1500mAh | |||||||

| 15 | Remote Controller | Hand remote control | |||||||

| 16 | Mode of Control | manual / Automatic Mode | |||||||

| 17 | Temperature of Warehouse | -18~40ºC(Normal)/ -30~-18ºC(Cryogenic) | |||||||

| 18 | Programmable Logic Controller | Siemens PLC | |||||||

| 19 | Voltage of Controller loop | DC 24V | |||||||

| 20 | Noise in Running | <70db | |||||||

Shorter unload times for pallets.

The Radio Shuttle modules (RSM) retrieve the pallets and bring them

to the aisle entrance so the forklift does not have to enter the lane

* Great for deep lane storage

* Allows the storage of different reference numbers per module and

therefore a higher number of stored references

* Lower risk of accidents

* Reduced reliance on forklifts inside lanes helps prevent rack damage

* By adding more RSMs, the flow of incoming and outgoing goods increases

* Optimizes space by compacting pallets with different widths inside

the channels

* Height between levels is minimized

* Improve Efficiency: Radio Shuttle brings the pallets to the entrance

so the forklift doe not have to enter lanes

* Increase Storage: Permits storage of different reference numbers per module

* Redcues Accidents

* Eliminate Lane Damage: Prevent the risk of rack damage since forklifts are

no longer needed ton enter the racking unit.

* Maximize Productivity: Simply by adding more carts, the flow of incoming

and outgoing goods increases.

*Highly Compatible: Optimizes space by compacting pallets with different

widths inside the lanes.

| Feature | 1.The engine is purchased from Germany, with brand of Lenze. The power is 550V. 2. The battery is Lithum. it could be working for 8 hours one time. 3. All the detectors are with brand of SICK. 4. The quality warranty is 12 months. |

Model | ||||||||||

| Item | parameter | RGV-500 | RGV-1000 | RGV-1500 | ||||||

| 1 | Suitable Pallets : | |||||||||

| 1.1 | Standard Pallet: L x W mm | W1200 X D1000mm | ||||||||

| 1.2 | Size Range Available :L x W mm | W1100 ~1250, D800 ~1100mm | ||||||||

| 1.3 | Styles of Pallet Bottom | "" or"" | ||||||||

| 1.4 | Material of Pallet | Wood,Plastics,Steel | ||||||||

| 1.5 | Deflection of Pallet | Max 20mm | ||||||||

| 2 | Total Weight of Loading | Max 500Kg | Max 1000Kg | Max 1500Kg | ||||||

| 3 | Model of Running | In the rails | ||||||||

| 4 | Data of Running: | |||||||||

| 4.1 | no load Running | 1.1m/s | ||||||||

| 4.2 | full load Running | 0.9 m/s | 0.7 m/s | 0.5 m/s | ||||||

| 5 | lift parameter | |||||||||

| 5.1 | Time of Single Lift | 2s | 2.3s | 2.5s | ||||||

| 5.2 | height of Lift | 40mm | ||||||||

| 5.3 | space between pallet and rail | 13mm | ||||||||

| 6 | specification of RSC: | |||||||||

| 6.1 | Outside Dimensions L x W x Hmm | L1100xW977x 198mm | ||||||||

| 6.2 | Weight of RSC | 242Kg | 268Kg | 300Kg | ||||||

| 6.3 | Plate Size of Equipment | L1030xW185xT3.5mm,2Pcs | ||||||||

| 6.4 | Inner Width of Fork | 230mm | ||||||||

| 6.5 | Width of Single Fork | 236mm | ||||||||

| 7 | Driver Motor for movement | Lenze 24V 370W | ||||||||

| 8 | Wheels of Running | φ120mm Vulkollan | ||||||||

| 9 | Driver Motor for Lifting | Lenze 24V 370W | ||||||||

| 10 | Battery Capacity | 24V 60AH | ||||||||

| 11 | Weight of Battery | 20Kg | ||||||||

| 12 | Charge times | 900 | ||||||||

| 13 | Duration of Charging | About 5 hours | ||||||||

| 14 | Method of Remote Control | Radio Frequency 433MHz,3.7V 1500mAh | ||||||||

| 15 | Remote Controller | Hand remote control | ||||||||

| 16 | Mode of Control | manual / Automatic Mode | ||||||||

| 17 | Temperature of Warehouse | -18~40ºC(Normal)/ -30~-18ºC(Cryogenic) | ||||||||

| 18 | Programmable Logic Controller | Siemens PLC | ||||||||

| 19 | Voltage of Controller loop | DC 24V | ||||||||

| 20 | Noise in Running | <70db | ||||||||

Hebei Woke Metal Products co Ltd founded in 1996, the headquarters and two sales company is located in Shijiazhuang hebei province, the production base is located in Hebei Xinhe industrial zone. We are partisan council unit of the China Storage & Distribution association/Hebei province modern logistics association and Hebei province e-commerce association. "HEGERLS" is ours registered trademark.

We can supply project plan design, supermarket and storage equipment and facilities installation, operation and management personnel training, supply series products, business planning and after-sales service, e-commerce etc. Our products and services has covered nearly 30 domestic provinces, cities and autonomous regions, products are exported to Europe, America, Middle East, Latin America, southeast Asia and other countries and regions. Annual sales of nearly 230 million yuan. More than 300 staffs, own production base and experimental centre, equipment research and development team, installation and after-sales service team, with senior technicians and senior engineer titles nearly 60. Company production base has the world advanced production assembly line 48.10 national patents of radio shuttle cart, stacker, mobile shelves, won the SGS, TUV certificate and ISO9001 certification.

In recent years, completed the domestic projects including: Sinopec storage project, Shanxi YunCang storage & distribution project, JiLin Long-Mart storage and distribution center project, Anguo Zhengtai Storage & distribution center project, Beiguo Goup supermarket chains, Guoda chain convenience stores, Hebei province expressway service area series of convenience stores and distribution centers, Junlebao dairy warehousing projects, etc.

Overseas projects: Sweden SwedMart warehouse project, Chile fisheries association Oscar refrigeratory AS/RS projects, Algeria FACTO storage projiects, Thailand JM Group AS/RS projects, FX Group South Africa AS/RS projects, AALM company UAE AS/RS projects. Automatic sorting stacker in FX Group South Africa AS/RS projects is domestic initiative within international leading level.

We can supply project plan design, supermarket and storage equipment and facilities installation, operation and management personnel training, supply series products, business planning and after-sales service, e-commerce etc. Our products and services has covered nearly 30 domestic provinces, cities and autonomous regions, products are exported to Europe, America, Middle East, Latin America, southeast Asia and other countries and regions. Annual sales of nearly 230 million yuan. More than 300 staffs, own production base and experimental centre, equipment research and development team, installation and after-sales service team, with senior technicians and senior engineer titles nearly 60. Company production base has the world advanced production assembly line 48.10 national patents of radio shuttle cart, stacker, mobile shelves, won the SGS, TUV certificate and ISO9001 certification.

In recent years, completed the domestic projects including: Sinopec storage project, Shanxi YunCang storage & distribution project, JiLin Long-Mart storage and distribution center project, Anguo Zhengtai Storage & distribution center project, Beiguo Goup supermarket chains, Guoda chain convenience stores, Hebei province expressway service area series of convenience stores and distribution centers, Junlebao dairy warehousing projects, etc.

Overseas projects: Sweden SwedMart warehouse project, Chile fisheries association Oscar refrigeratory AS/RS projects, Algeria FACTO storage projiects, Thailand JM Group AS/RS projects, FX Group South Africa AS/RS projects, AALM company UAE AS/RS projects. Automatic sorting stacker in FX Group South Africa AS/RS projects is domestic initiative within international leading level.

More >