Home Rack Products Parker 800 Kgs Electric Vacuum Glass Holder and Lifter

Parker 800 Kgs Electric Vacuum Glass Holder and Lifter

| Price: | US $ 1800-2800/Set |

|---|---|

| Trade Terms: | FOB,CIF |

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T,Western Union,Money Gram |

Parker 800 KGS Electric Vacuum Glass Holder And Lifter

PARKER Vacuum Lifter Design Result:

PARKER Vacuum Lifter Performance indicators:

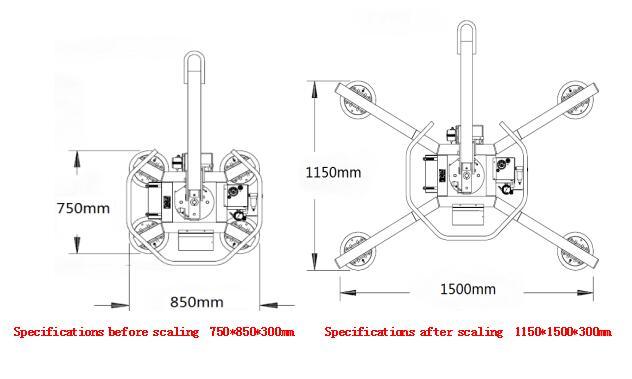

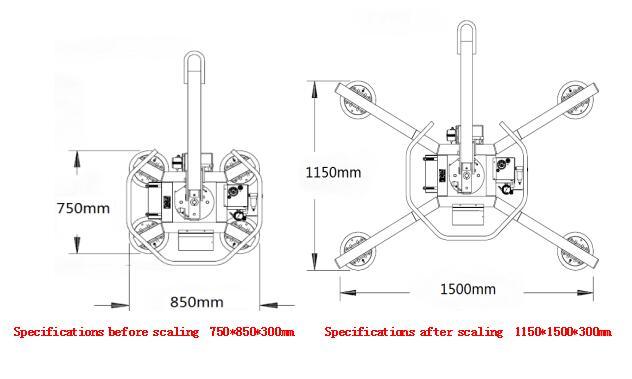

PARKER Vacuum lifter approximate product outline drawing:(Optional for extension rod )

PARKER Vacuum lifter flexible configuration:

1,Beam and suction cup's position can adjustable: all the position of the beam on the main girder can be conveniently manually adjusted , each suction cup on the beam can also convenient adjustment, thus ensure the crane adapted to the different size of workpiece.

2,Suction cup's quantity can adjustable: each cup is equipped with manual ball valve, so the small size plate can close those don't required, also can be used in the vacuum system tightness self-inspection.

3,Suction cup seal character guarantee: vacuum cup's lip design to ensure the reliability of the seal, and the connect rod of cup is equipped with two springs on up and down to ensure that every suction cups are in contact with the plate, and reach uniform distribution the force.

PARKER Vacuum lifter brief usage introduction:

1,Vacuum lifter and crane connection:

Mechanical: first of all fastening crane hook to the vacuum lifting lug;

Electric: connect the vacuum lifter's aviation plug to the crane's aviation plug, and at the same time start the master switch, then the vacuum pump start working.

2,Vacuum lifter positioning: control crane's movement, make the vacuum lifter's center close to the center of plate gravity, then put the vacuum lifter on the plate, at that time the vacuum lifter self weight is on each of the suction cup's spring rod and the connection ball head, make fully fit for each suction cup and sealing plate surface.

3,Glass adsorption: push the handle on the push & pull valve, at that time the suction cups and vacuum system are connected. Vacuum lifter will automatic adsorb the glass and gauge will be displayed in vacuum (pressure) at this time , it means can undertake handling when the pressure gauge shows 60% vacuum (0.6 kg/f)

4,Glass handling: control the crane movement to the specified location and to be ready for assembly.

5,Glass releasing: Push the handle on the manual slide valve, make each sucker and atmosphere are interlinked, then suction cups and vacuum pressure between the glass surface will disappeared, so the glass will separate from suction cups.

6,Repeat operation: manipulation of the crane movement to the next sheet for handling, repeat steps (1).

PARKER Vacuum Lifter Design Result:

| Vacuum Lifter | P/N:FVL-G800-8,suction 800KG |

| Specifications before scaling | 850mm*750mm*300mm(L*W*H) |

| Specifications after scaling | 1500mm*1150mm*300mm(L*W*H) |

| Handling way | By manually can flip 90 degrees and rotate 360 degrees PARKER features: using human body mechanics, movement joint type, automatic braking, complete roll using small force to complete rolling |

| Safety tank volume | About 5L |

| Control handle specifications | The integrated control unit |

| Vacuum suction pad units | Roundity,8 units,each suction pad test out the result 100kgf under the condition of 60% vacuum pressure(4 times safety coefficient) |

| Oil-free vacuum pump | America THOMAS pump,1 pcs,Ultimate vacuum pressure is 72% |

| Vacuum Lifter | P/N:FVL-G400-4,suction 400KG |

| Specifications scaling | 850mm*750mm*300mm(L*W*H) |

| Handling way | By manually can flip 90 degrees and rotate 360 degrees PARKER features: using human body mechanics, movement joint type, automatic braking, complete roll using small force to complete rolling |

| Safety tank volume | About 5L |

| Control handle specifications | The integrated control unit |

| Vacuum suction pad units | Roundity,4 units,each suction pad test out the result 100kgf under the condition of 60% vacuum pressure(4 times safety coefficient) |

| Oil-free vacuum pump | America THOMAS pump,1 pcs,Ultimate vacuum pressure is 72% |

PARKER Vacuum Lifter Performance indicators:

| Project content | Performance indicators |

| Rated load | 800kg glass can horizontal & vertical displacement handling(under the condition of 60% vacuum pressure) |

| Safety factor | 4 times,passed ISO9001 system testify:2008;Comply with European CE safety regulations |

| Safety alarm | System vacuum pressure lower than 60%,buzzer (with independent rechargeable battery) will send out sound and light alarm signal |

| Pressure holding time | Cut off power supply, the time required is greater than or equal to 10 min. of system vacuum pressure drop by the supreme to 60% |

| Suction & Release Control | Two position & three links manually slide valve (safety lock to prevent wrong operation) |

| Noise index | Less than 65dB(A) |

| Lifting part's weight | 80kg(similar) |

PARKER Vacuum lifter approximate product outline drawing:(Optional for extension rod )

PARKER Vacuum lifter flexible configuration:

1,Beam and suction cup's position can adjustable: all the position of the beam on the main girder can be conveniently manually adjusted , each suction cup on the beam can also convenient adjustment, thus ensure the crane adapted to the different size of workpiece.

2,Suction cup's quantity can adjustable: each cup is equipped with manual ball valve, so the small size plate can close those don't required, also can be used in the vacuum system tightness self-inspection.

3,Suction cup seal character guarantee: vacuum cup's lip design to ensure the reliability of the seal, and the connect rod of cup is equipped with two springs on up and down to ensure that every suction cups are in contact with the plate, and reach uniform distribution the force.

PARKER Vacuum lifter brief usage introduction:

1,Vacuum lifter and crane connection:

Mechanical: first of all fastening crane hook to the vacuum lifting lug;

Electric: connect the vacuum lifter's aviation plug to the crane's aviation plug, and at the same time start the master switch, then the vacuum pump start working.

2,Vacuum lifter positioning: control crane's movement, make the vacuum lifter's center close to the center of plate gravity, then put the vacuum lifter on the plate, at that time the vacuum lifter self weight is on each of the suction cup's spring rod and the connection ball head, make fully fit for each suction cup and sealing plate surface.

3,Glass adsorption: push the handle on the push & pull valve, at that time the suction cups and vacuum system are connected. Vacuum lifter will automatic adsorb the glass and gauge will be displayed in vacuum (pressure) at this time , it means can undertake handling when the pressure gauge shows 60% vacuum (0.6 kg/f)

4,Glass handling: control the crane movement to the specified location and to be ready for assembly.

5,Glass releasing: Push the handle on the manual slide valve, make each sucker and atmosphere are interlinked, then suction cups and vacuum pressure between the glass surface will disappeared, so the glass will separate from suction cups.

6,Repeat operation: manipulation of the crane movement to the next sheet for handling, repeat steps (1).

If need more details, please kindly reply or contact below:

Contact | Carina Zhang |

Company | PARKER MACHINERY CO.,LTD,CHINA |

Mobbile | +86-15106958367 |

Website | http://www.parker-chn.com |

Industrial Park add: | Mingjia West Road, Qihe, Shandong, China |

| Prod Model: | GAC-6 |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Specifications Before Scaling: | 850mm*750mm*300mm |

| Specifications After Scaling: | 1500mm*1150mm*300mm |

| Safety Tank Volume: | 5L |

| Weight: | 80kgs |

| Function: | Electric Vacuum Glass Holder and Lifter |

| Control Handle: | The Integrated Control Unit |

Parker Machinery Co., Ltd., China has developed the assembly line equipment for door-window, curtain walls and Insulating glasses process. The operation of high precision, advancement and specialty makes the enterprise well-known. She sets an example for her pure quality and excellent service. So she becomes the reliable cooperative partner of the door-window enterprise for her responsibility.

Parker machines sell well, become well-known and outstanding at the national fairs of door-window equipment, owing to:

Using of European standards, and taking in the view and pithy of the design.

Purchasing main parts internationally.

Selling machines to other countries, such as USA, India, UAE, Brazil, Iran, North America, South Africa, Russia, Korea, Middle East, and so on.

Carrying our "Handover key project" ahead of other in this area.

Combining the manufacture with the development of design software of door-window.

Owing more than twenty sales and service agencies.

To meet the great need of development of hi-grade door-window, combining with almost ten years of experience, we introduced advanced technology from other countries, and developed five types, more than forty specifications of door-window and curtain wall equipment. Door-window factories needn't import any hi-grade machine from other countries any more.

Let's share science and technology of the world!

Parker machine core parts procurement achieved internationalization, and established a cooperative partnership with ABB, Omron, Schneider, Optima. PARKER people are always follow the core concept, it is "Parker is developing with the world", it is PARKER peoples' strict implementation of ecological system of Parker and of "zero defect" stern pursuit, which makes the Parker machine perfect implement unique global standard, achieves improvement value and sustainable innovation!

Parker machinery exports to the world more than80 countries and regions, and has firstly established branches in USA, India, UAE, Brazil, has 50 patents. PARKER products include aluminum, PVC windows and doors machinery, aluminum curtain wall processing machinery, industrial aluminum processing machinery and insulating glass series production line machinery. Parker machinery are all passed through high standard European CE certification, American UL certification and Canadian CSA certification.

Parker machines sell well, become well-known and outstanding at the national fairs of door-window equipment, owing to:

Using of European standards, and taking in the view and pithy of the design.

Purchasing main parts internationally.

Selling machines to other countries, such as USA, India, UAE, Brazil, Iran, North America, South Africa, Russia, Korea, Middle East, and so on.

Carrying our "Handover key project" ahead of other in this area.

Combining the manufacture with the development of design software of door-window.

Owing more than twenty sales and service agencies.

To meet the great need of development of hi-grade door-window, combining with almost ten years of experience, we introduced advanced technology from other countries, and developed five types, more than forty specifications of door-window and curtain wall equipment. Door-window factories needn't import any hi-grade machine from other countries any more.

Let's share science and technology of the world!

Parker machine core parts procurement achieved internationalization, and established a cooperative partnership with ABB, Omron, Schneider, Optima. PARKER people are always follow the core concept, it is "Parker is developing with the world", it is PARKER peoples' strict implementation of ecological system of Parker and of "zero defect" stern pursuit, which makes the Parker machine perfect implement unique global standard, achieves improvement value and sustainable innovation!

Parker machinery exports to the world more than80 countries and regions, and has firstly established branches in USA, India, UAE, Brazil, has 50 patents. PARKER products include aluminum, PVC windows and doors machinery, aluminum curtain wall processing machinery, industrial aluminum processing machinery and insulating glass series production line machinery. Parker machinery are all passed through high standard European CE certification, American UL certification and Canadian CSA certification.

More >