Home Rack Products LED Light Housing Aluminium Die Casting

LED Light Housing Aluminium Die Casting

| Price: | US $ 15.3-18.6/Piece |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 500/Piece |

| Pay Type: | L/C,T/T,Western Union,Paypal,Money Gram |

Black anodizing light base LED light housing aluminum die casting process

Product Description

Product details:

1. Technology: die casting, aluminum die casting process

2. Material: zinc, zamak, za-8, za-12,aluminum, alloy, a 380

3. Surface treatment: anodized, black anodize, painting

Products:

| Item | Black anodizing light base LED light housing aluminum die casting process |

| Technology | Die casting |

| Die casting | Die casting and injection die casting |

| Material | Aluminum, alloy, zinc, zamak, plastic, PA 66 |

| Machining | Tapping, grinding, drilling, threading, milling |

| Finish | Anodizing, powder coating, hot-dip galvanizing |

| Tolerance | +/-0.01mm |

| Application | Construction machinery parts, auto parts, industrial parts |

Company Information

Qingdao Xinghe Machinery Co.,Ltd. Jointly manufactures and exports a variety of casting products for architectural, automotive, mechanical parts. We export to more than 20 countries on 6 continents and have been doing so for more than 10 years. Our main product line includes sand casting, precision casting, die casting,forging and CNC turning. Materials vary from grey iron, ductile iron, bronze, aluminum, steel, stainless steel, and so on. We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

Die Casting factory:

Casting tolerance: CT9-CT12

Standards: GB, ASTM, SAE, ISO, EN, DIN, JIS, BS

Piece weight: Al 50 g - 100 kg

Machining workshop:

Heat treating: Discharge, carbonization, tempering, normalization and surface tempering

Surface finishing: Grinding, polishing, painting and various coatings

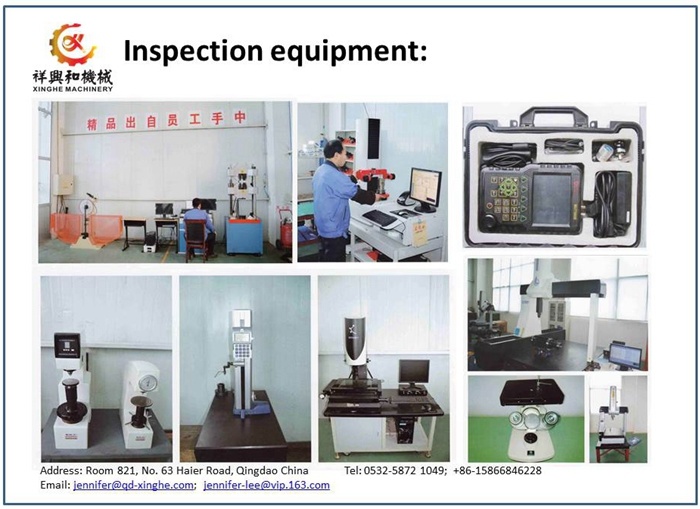

Inspection equipment:

In order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

Packaging & Shipping

1. Plastic bag

2. Carton box, wooden box

3. Pallet

4. As customers' requirment

Our Services

1) Experience in casting for many years and served customers all around the world.

2) International advanced-level equipment such as CNC, numerical lathes, CMM.

3) OEM service, you demand is our pursued.

4) ISO quality control

FAQ

1. How can I get the quotation?

Please send us information for quote: drawing, material, weight, quantity and request.

2. If we don't have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 25-30 days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time: 35-40 days after the payment. The accurate time depends on your product.

5. What is your payment method?

Tooling: 100% TT advanced.

Main order: 50% deposit, balance 50% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..

7. If you export to our country before, can I get the information of your import customer in our country?

We can't offer you all the information of our customer because we have duty to protect our customers' privacy. But we can provide you some part of B/L.

| Prod Model: | aluminum casting |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Name: | LED Light Housing Aluminium Die Casting |

| Technology: | Die Casting |

| Other Material: | Aluminum, Alloy |

| CNC: | Drilling, Tapping, Grinding |

| Surface: | Polishing, Power Coated, |

| Place Of Orgin: | Shandong; China |

| Tolerance: | +/-0.05mm |

| Heat Treatment: | Quenching |

| Delivery Time: | 30 Days After Payment |

| Packaging: | Pallet for Housing |

| Material: | Aluminum Alloy |

| Surface Preparation: | Spray Coating |

Qingdao Xinghe Machinery Co., Ltd. Jointly manufactures and exports a variety of casting products for architectural, automotive, mechanical parts. We export to more than 20 countries on 6 continents and have been doing so for more than 10 years.

Our main product line includes sand casting, precision casting, die casting, forging, stamping, welding and CNC machining. Materials vary from grey iron, ductile iron, bronze, aluminum, steel, stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

Moreover, in order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1) Incoming material inspection

(2) Inspection of work-in-progress

(3) Finished product inspection

(4) Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.

Our main product line includes sand casting, precision casting, die casting, forging, stamping, welding and CNC machining. Materials vary from grey iron, ductile iron, bronze, aluminum, steel, stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

Moreover, in order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1) Incoming material inspection

(2) Inspection of work-in-progress

(3) Finished product inspection

(4) Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.

More >